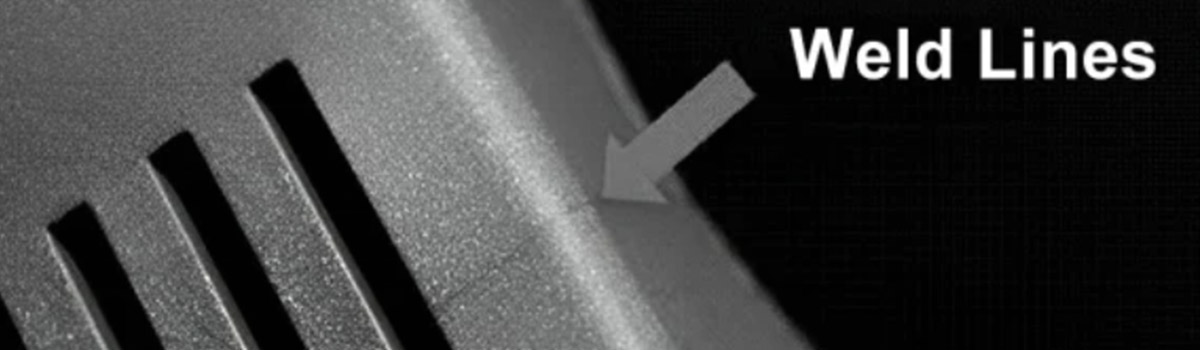

Injection Molding Weld Line

Image Description: A close-up image of a plastic injection molded part showing a visible weld line, with the area clearly highlighted by overlaid text.

Any defect in the finished part will leave you unsatisfactory. When it comes to injection molding, even a minimal defect could considerably impact the quality of the item. One such cause is the injection molding weld line. Although it seems a minor quality concern, it has a severe impact on product appearance and the structural integrity of the finished item. To avoid such issues, this article will evaluate major reasons for weld lines, their potential impact, and prevention methods.

What are Injection Mold Weld Lines?

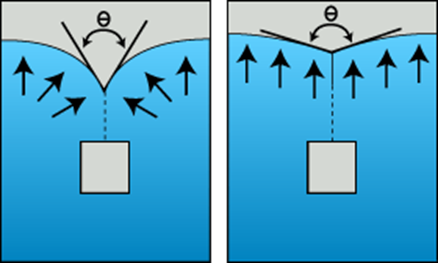

Also known as knit lines, they show the joining point between two mold flows during injection molding. They are produced due to uneven joining of both fronts. They are not just an appearance issue. These lines may weaken the part and lower its overall performance. Another terminology used for this molding defect is meld line. One major difference between both is that in the weld line, the meeting angle is lower than 135 degrees and vice versa.

Weld Line (Ө < 135) Vs Meld Line (Ө > 135)

Image Description: A side-by-side comparison image showing a Weld Line with a convergence angle less than 135° and a Meld Line with an angle greater than 135°.

How Weld Lines Form

Whenever the flow of molten plastic is shattered or split, weld lines are formed. Immediately upon these flow fronts reconnect, the material does not always bond seamlessly. There could be many reasons for this:

- Multiple flow paths caused by complex part geometry

- Inappropriate material cooling or low mold temperature

- Poor flow control in the mold design

Visual and Structural Impact

Weld lines affect both the appearance and strength of the part. Visually, they can leave unsightly lines or seams on the product surface. They generate weak spots that can crack and fail structurally under stress.

What Are The Causes of Injection Molding Weld Lines?

Several factors lead to the formation of weld lines, and many of these are related to the mold design, processing parameters, material properties, and part geometry. These causes will help you diagnose and minimize weld line issues.

Material Flow Issues

Material Flow Issues

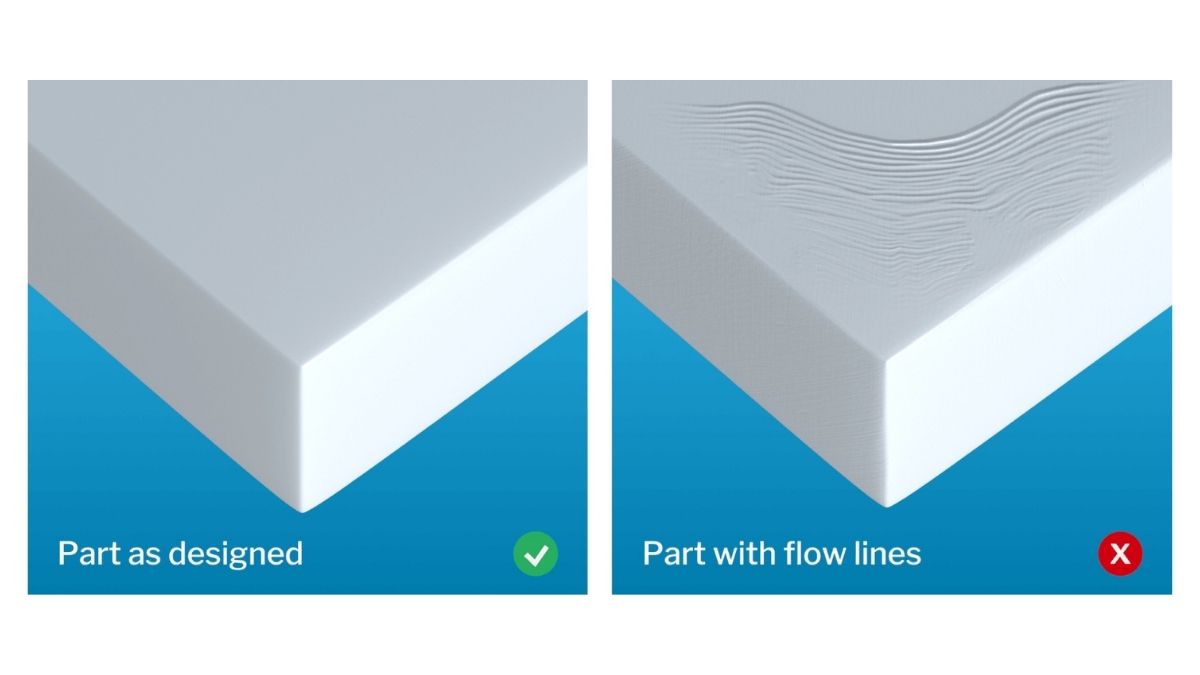

Image Description: A close-up image demonstrating material flow issues in injection molding, featuring side-by-side comparisons of correct and incorrect flow patterns.

One of the main causes of weld lines is uneven or interrupted material flow. In molten plastic, when the plastic flows around obstacles (holes, ribs, etc.), the flow fronts meet and do not fuse properly. Premature cooling of the material can occur at low injection speed and cause weak welds.

Poor Mold Design

Material flow is dependent on mold design. Unintended flow paths that collide can generate weld lines if the gates are in the wrong place. Trapped air in the mold is an inadequate venting, which prevents the air from leaving the mold, thereby preventing complete fusion at the weld points. In addition, material flow can be unpredictable because of sharp corners and unnecessary complexity in the mold design.

Incorrect Processing Parameters

Another major contributor is improper control of processing parameters. Low mold temperatures shorten the time available for the molten plastic to fuse properly. Inadequate injection speed and pressure can also cause early cooling and weak weld lines.

Material Properties

High-viscosity materials are more difficult to flow and more prone to weld lines. Incompatible materials, especially when blending additives or fillers, can also hinder proper fusion at the weld point.

Part Geometry

As the part geometry becomes more complex, the formation of multiple flow fronts is more likely. Features like thin walls, holes, or ribs can disrupt the flow and make weld lines. To reduce this risk, it is critical to optimize the geometry to simplify flow paths.

Effects of Injection Molding Weld Lines on Product Quality

A molded part with weld lines can be both aesthetically and functionally undesirable. Weld lines’ impact on applications varies from minor visual defects to serious structural weaknesses that can jeopardize product performance.

Aesthetic Defects

From a visual standpoint, weld lines are surface marks or seams that may be apparent on finished products. These defects can greatly impact the perceived quality of consumer-facing products. Color variations and uneven surface textures at the weld lines are common and especially troublesome for high-gloss finishes.

Structural Weakness

The part, in general, is a weak area around a weld line. The rest of the material has a stronger mechanical bond between the two flow fronts. This weakness can cause cracks or failures under mechanical stress, especially in load-bearing parts or parts subjected to repeated stress cycles.

Functional Issues

Weld lines reduce strength but can also cause functional problems. For example, they may leak at the part exposed to high pressure. Weld lines in electrical components can be stress concentrators that increase the risk of failure during operation. Therefore, minimal weld lines are necessary in such applications.

How Can You Avoid Injection Molding Weld Lines?

To avoid weld lines, mold design needs to be optimized, processing parameters adjusted, suitable materials selected, and part design improved. Advanced molding techniques can also be used to reduce or eliminate weld lines in complex parts.

Optimize Mold Design

Mold design with good weld line minimization is important. Emphasize the gate placement so that the material flows uniformly and does not create extra flow fronts. Moreover, the trapped air will be released with the help of vents at strategic locations to improve material fusion. Symmetrical designs and smooth transitions are used to encourage unbroken flow.

Adjust Processing Parameters

The injection molding parameters can be fine-tuned and make a big difference. Slow the cooling rate by increasing the mold temperature and improving the fusion of the material. Make sure the injection speed and pressure are optimized so that the flow is smooth and uninterrupted. Reducing cycle time can also reduce premature cooling.

Advanced Techniques

Think about advanced molding technologies for complex parts. Hot runner systems maintain temperature and avoid premature cooling. Sequential valve gating allows for precise control of material flow, and flow fronts meet optimal conditions for fusion.

Material Selection

It is important to choose the right material. Low-viscosity materials flow better and reduce the chance of welding lines. For high-performance applications, engineers prefer materials that resist weld line formation. Check compatibility when blending materials to avoid bonding problems.

Testing and Quality Control

Detection and addressing weld lines require effective quality control. Regular testing, process monitoring, and simulation help guarantee consistent product quality.

Identifying Weld Lines

The first step in identifying weld lines is visual inspection. Telltale signs are surface defects such as thin seams or color variations. Machinists use non-destructive testing (NDT) methods such as ultrasonic testing or X-ray inspection to detect internal weaknesses resulting from weld lines for critical parts.

Part Design Improvements

Simplifying the part geometry can reduce weld lines. Do not use thin walls or sharp transitions. In addition, fillets and rounded edges encourage even material flow. Design with flow simulation in mind to predict and avoid potential weld line locations.

Simulating Flow Behavior

The mold flow analysis software makes weld line prediction and prevention possible. It enables engineers to see how the molten material will flow in the mold. By identifying potential problems early, design and process changes can be made before the product is produced.

Ongoing Improvements

Once defects are identified, quality control does not stop. Continuous monitoring and improvement in the process is the only way to keep high standards. Monitor key process parameters, implement corrective actions, and regularly update your molding processes to reduce defects. Root cause analysis can also be used to identify recurring issues and improve manufacturing procedures.

Testing Standards and Methods

The following procedures help manufacturers to early find and eliminate these weld lines:

- Simulation tools: Various mold flow software can be utilized to predict the probability of weld lines early on. This helps engineers optimize products in the design stages.

- Visual Inspection: In this method, look for variations in colors, uneven surfaces, or lines on the product surface. Operators perform this under sufficient light for clear identification.

- Mechanical Testing: Standards like ASTM D638 are used for tensile testing. Manufacturers use this to select material that meets strength criteria.

- Non-destructive testing: Engineers use these testing approaches to detect a product’s internal weaknesses using X-ray or ultrasonic inspection.

- Micro-CT Scanning: This scanning helps manufacturers visualize 3D internal structures to find critical regions.

When used together, these methods allow you to achieve a smooth enhancement of product quality. Testing routines detect product defects while simultaneously ensuring optimal operational results. The manufacturing process results in fewer product failures and satisfied customers.

Final Thoughts

Injection molding weld lines might look like a minor issue, but they can have a significant impact on both the appearance and strength of the end product. The good thing? They‘re manageable. By improving mold design, selecting good materials, and tuning your process, you can reduce or even eliminate such defects. Don’t forget the impact of effective testing and continuous improvement. These factors confirm that the product remains durable and top-notch over time. With the right approach, you can turn potential weaknesses into strengths, delivering products that not only look great but also perform flawlessly under pressure. It’s all about combining science, strategy, and a commitment to quality.

Choose Premium Parts for Premium Quality Injection Molding Services

Whether you are prototyping or scaling production, partnering with a trusted manufacturing partner will help. We at PremiumParts offer high-quality injection molding services that are custom-made according to your requirements. Our state-of-the-art equipment and mold flow analysis, combined with our expert engineering team, produce your parts to the highest quality standards.

With us, it’s not just about removing the defects. It’s about creating an item that stands the test of use and time. We can provide customized solutions ranging from small-scale to mass-production. Are you ready to produce defect-free, high-performance molded parts? Contact Premium Parts and turn your project into a success. We will make your vision a reality with precision, quality, and unmatched service.

FAQs

Q1: Can weld lines be removed completely?

They are difficult to eliminate, but you can reduce them dramatically by good design and advanced molding techniques.

Q2: What impact does the weld line have on part strength?

Indeed, weld lines are weak spots of the part at the junction of two flow fronts, increasing the risk of cracks and failures under stress.

Q3: What type of materials tend to have weld lines?

Weld lines are most likely to occur on high-viscosity material or material blends that are incompatible.

Q4: In what types of molds are weld lines more common?

Of course, weld lines are more likely to occur on complex molds with multiple gates or poor venting.