Different Types of Lathe Cutting Tools

Image Description: The image depicts a variety of lathe-cutting tools arranged side by side, including turning tools, facing tools, parting tools, threading tools, boring bars, and grooving tools, each with distinct shapes and cutting edges.

Every machining project starts with a critical decision. For example, the choice of the cutting tool, machine selection, and budget. From all choices, selecting the right tool is imperative. Using an unsuitable cutting tool can badly impact your part, as it will cause excessive tool wear. In the end, catastrophic failure is inevitable. In reverse, the right lathe cutting tool usage can improve productivity, increase precision, and greatly extend tool life.

If you are a design engineer working on complicated aerospace parts or a machinist making car components, the right choice of cutting tool is vital for obtaining accurate specifications. A massive world of CNC lathe cutting tools offers custom-made solutions for different materials and operations. This article focuses on the classifications of different cutting tools used in lathe machines and how to choose the right one.

What Is a Lathe Machine?

Lathe Machine

Image Description: A full view of a lathe machine featuring a rotating spindle, tool post, chuck, and bed.

A lathe machine turns workpieces by rotating them against a fixed cutting tool, removing excess material. It also performs operations such as turning, facing, drilling, boring, and threading. CNC (Computer Numerical Control) lathes advance the traditional machine tool by automating these processes for relatively high precision and efficiency.

Cylindrical shapes or parts such as shafts, bushings, and gears are only produced on lathe machines. Consequently, modern-day CNC lathes can achieve tight tolerances, which makes them central for various manufacturing sectors such as aerospace, automotive, and medical device manufacturing.

CNC Machines Lathe Cutting Tools By Type

Choosing the correct tool for the job can be the difference between successful or unsatisfactory machining outputs. Using the wrong tool will cause bad finishes, excessive wear, and expensive downtime. But make the right choice, and you can maximize production, precision, and minimal material wastage during operations. Let’s take a glance at various types of lathe-cutting tools.

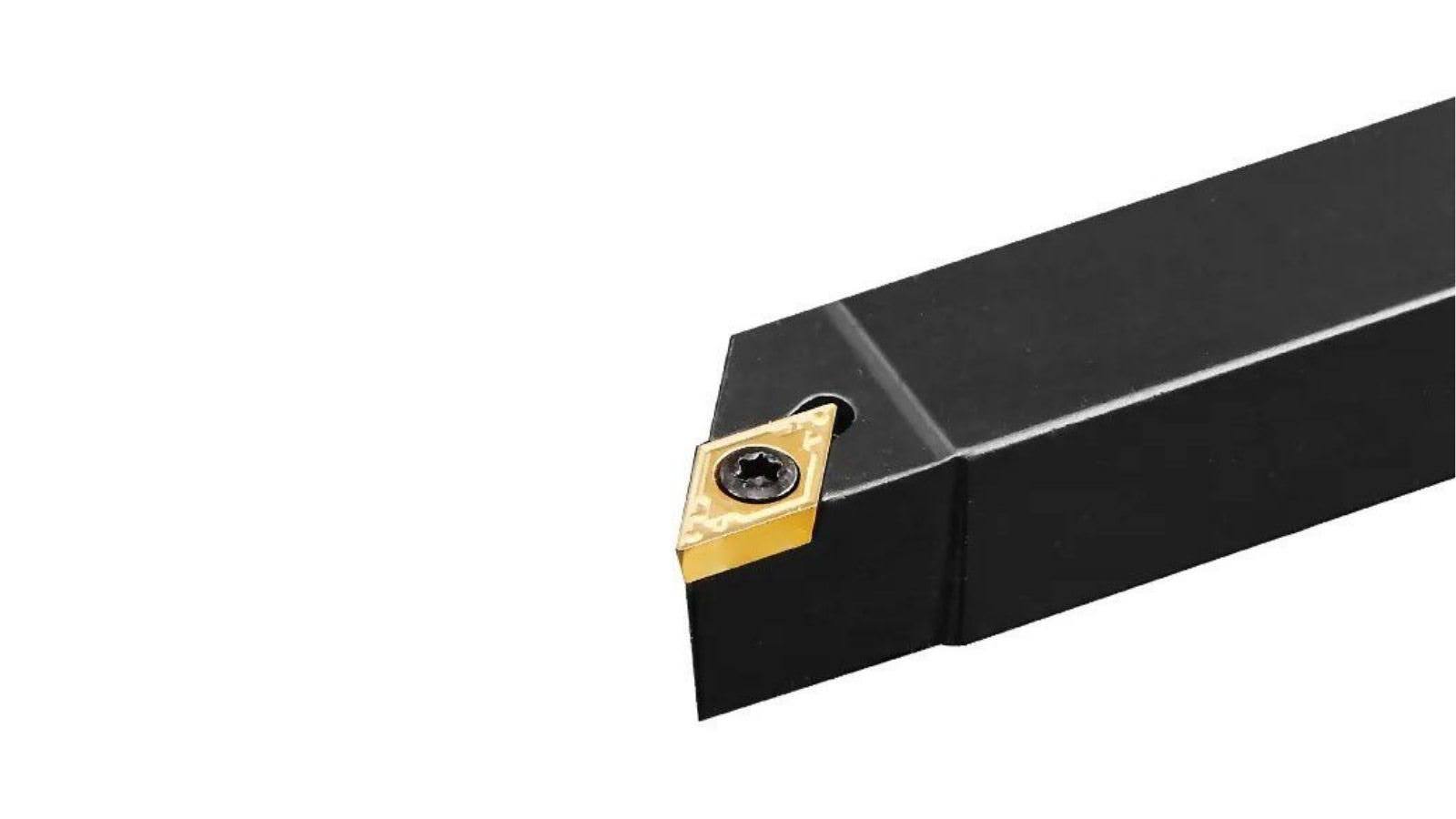

Turning Tools

ISO 3685:1993: Tool-life testing of single-point turning tools.

Turning tools remove material from the outer (cylindrical) surface of a rotating workpiece, decreasing the diameter or yielding specific profiles.

- Rough turning: These tools are suitable for rapid material removal. They are used in earlier phases to set up the workpiece for finishing.

- Finish Turning Tools: The final pass meets the surface finish and dimensional accuracy.

Lathe Turning Tool

Image Description: A close-up view of a lathe-turning tool with a sharp cutting edge.

Facing Tools

ISO 5608:2019: Standard covers turning tools with inserts made of carbide for facings.

Facing tools generate flat surfaces by cutting on the ends of the workpiece. In operation, the tool travels in a crosswise direction to the workpiece axis. It provides high values of flatness and perpendicularity, which are fundamental for part types such as flanges and covers.

Facing Tool

Image Description: A close-up image of a facing tool for a lathe featuring a straight cutting edge. It is designed to create flat surfaces at the end of a workpiece.

Boring Tools

ISO 10889-7:2011: Modular taper tool holders for boring operations

The boring tools are used to increase the size of pre-drilled holes or to finish holes to high precision. Hole accuracy and surface finish for parts that must be within tolerance specifications, such as H7 or H8 grades, are improved by using these tools.

Boring Tool

Image Description: A close-up image of a boring tool with a slender, extended cutting tip. It is designed to enlarge or finish the internal diameter of a hole on a lathe.

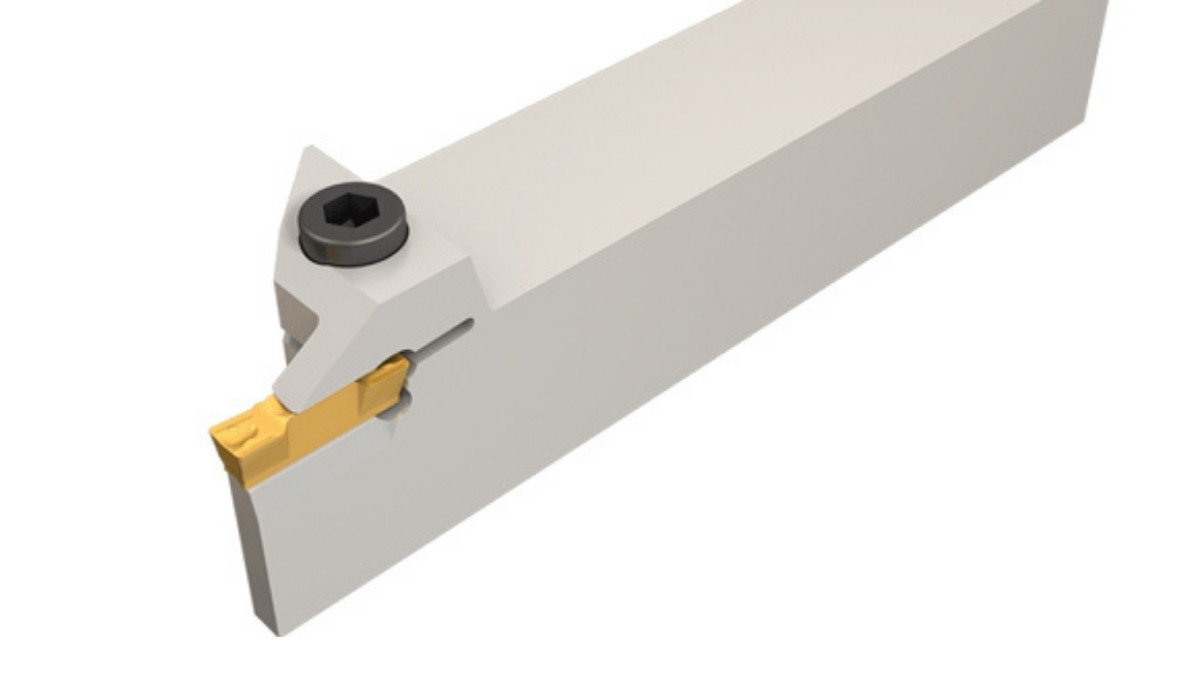

Grooving Tools

ISO 13399-3:2014: Slotting & Grooving operations

Grooving tools produce narrow channels or slots in a workpiece for features such as O-ring grooves and snap-ring slots. Insert-based grooving tools can accommodate different groove widths and depths.

Grooving Tool

Image Description: A close-up view of a grooving tool with a narrow-shaped cutting edge. It is designed to cut grooves or recesses into the outer or inner surface of a rotating workpiece.

Threading Tools

ISO 68-1:1998: Generic profile for Iso metric screws

A threading tool helps develop external or internal threads on a workpiece. It is commonly used for metric, unified, and pipe threads; CNC threading offers high dimensional accuracy and repeatability in operation.

Threading Tool

Image Description: A simple close-up image of a threading tool with a pointed cutting tip displayed.

Chamfering Tools

ISO 3002-2:1982: Guide to chamfering and deburring tools.

Chamfering tools work to create beveled edges on a workpiece, effectively removing sharp corners or prepping parts for assembly. Chamfering refers to the last step for seamless surface transitions. It improves parts’ functionality and aesthetic value.

Chamfering Tool

Image Description: A simple close-up image of a chamfering tool with an angled cutting edge.

What Are Lathe Cutting Tools Made of?

The tool material is critical to the performance of the machining process. It impacts speed, accuracy, and tool life directly. That is why manufacturers must understand the significance of choosing the appropriate tool material, as they can maximize efficiency and create exact results. The following are the top materials for CNC lathe-cutting tools:

High-Speed Steel (HSS): Reasonable and Dependable

ISO 4957:2018: Tool Steels

HSS is commonly used for general-purpose operations. It provides decent toughness and is easy to sharpen, making it well-suited for operations at low to medium speeds. HSS tools are usually employed to machine softer materials like aluminum, brass, and mild steel. They are relatively cheaper but do not last as long as carbides or ceramics.

High-Speed and Accurate Carbide Tools

ISO 513:2012: Classification of Carbide Tool Materials

Carbide is much harder and resistant to heat. It can endure a higher speed of cutting than HSS tools. Thus, carbide tools are typically preferred by engineers for machining harder materials such as stainless steel, titanium, and cast iron. These tools give excellent surface finishes and longer tool life, resulting in less downtime and maintenance costs.

Ceramic Tools: Extreme Resistance to Wear

ISO 3685:1993: Tool-Life Testing of Ceramic Tools

Ceramic tools are ideal for high-velocity applications and processing. They are well suited to cutting superalloys, hardened steel, and cast iron and for machining operations on highly wear-resistant parts. These tools are widely used in the aerospace and automotive industries, where precision and speed are critical. But ceramic tools are brittle, needing a stroke of care.

Highest Durability: Diamond Tools

ISO 1832:2017: Cutting tool inserts with diamond coatings

Diamond tools are the toughest and the most wear-resistant. These provide exceptional accuracy and are useful for processing non-ferrous materials, composites, and ultra-hard alloys. Moreover, the final layers of polish that these tools help provide are critical in industries that demand ultra-fine finishes like electronics and optics. They cost a lot, but they are very durable, so you get a good long-term investment.

Coated Tools: Optimal Performance

Coatings like titanium nitride (TiN) and aluminum oxide (Al₂O₃) impair tool performance. Moreover, coatings help minimize friction and heat buildup, increasing tool life. Coated tools are typically used for high-speed and abrasive machining.

How to Choose the Right Lathe Cutting Tools?

Choosing the correct lathe cutter is the key to lathe machining success. No two projects are the same, so many factors need to be taken into account to get the most out of what you have. Using the wrong tool can result in tool breakage, poor surface finish, and additional expenses. Let’s discuss the main considerations in choosing the right tool.

Keep the Workpiece Material in Mind

Tools for different materials differ from one another.

- Soft Materials (Aluminum, Brass): HSS or carbide tools will work very well.

- Hard Materials (Steel, Titanium): Use carbide or ceramic tools for better wear resistance.

- For Non-Ferrous Materials and Composites: Diamond tools provide long-lasting, efficient performance.

Knowing what workpiece material you are dealing with will prevent tool damage and ensure the best possible outcome.

Additional Emphasis on Surface Finish and Tolerances

In many domains, precision is key. Roughing operations rapidly remove large quantities of material. Finishing tools are, however, necessary for tight tolerances and smooth surfaces. Select tools with the correct geometry for what finish you are trying to achieve.

Check Tool Geometry

Tool geometry influences performance and efficiency. The rake angle, clearance angle, and nose radius should be consistent with the cutting conditions. Well-designed geometry lowers cutting forces and heat generation, extending tool life.

Machine Compatibility

Make sure that your CNC lathe is compatible with the tool. Compatibility also depends on spindle speed, tool holding system, and machine rigidity. Incompatible tools can damage the machine or cause performance loss.

Cost vs. Performance

Always invest in the right tools, as high-end quality makes all the difference in how well a tool works and how long it lasts. But cheaper tools wear out sooner and can affect your part quality. Therefore, buy the tools with the best cost-to-performance ratio.

Tool Coatings for Longevity

They increase tool life and lower friction. Titanium nitride (TiN) coatings enhance wear resistance. (Al₂O₃) coatings provide oxidation protection at high temperatures during high-speed machining. These coatings can drastically increase the tool’s life and efficiency.

Tailor Your Selection

Set aside time to evaluate each project’s requirements. Choose based on material type, surface finish, geometry, and machine compatibility. Choosing the ideal tool minimizes downtime, enhances quality, and amplifies productivity.

Common Mistakes to Avoid

Even seasoned machinists can make mistakes when choosing or using lathe-cutting tools. Errors in machining can lead to significant problems, including poor surface finish, tool failure, and costs. Let’s walk through a few frequent mistakes and how to avoid them.

Overlooking Tool Material Compatibility

Choosing inappropriate tool material for some workpieces causes high tool wear and low efficiency. For instance, machining Allen bars with HSS will result in quick tool wear. When selecting a tool material for the workpiece, always ensure they complement each other.

Incorrect Tool Geometry

Using the incorrect rake or clearance angle will decrease your cutting efficiency and increase heat. Because of this, tool breakage and chipping occur frequently. Be sure to use tool geometry that matches your cutting conditions for the best results.

Neglecting Tool Wear

Maxing out tool usage can hinder part quality and ruin the machine. Regular checks and replacements are compulsory. Worn tools produce rough finishes and make people dimensional inaccurate.

Ignoring Machine Capability

Using tooling that does not match your machine spindle speed or tool holder can lead to excess vibration or tool chatter. This compromises accuracy and raises the likelihood of tool breakage. So, be sure to verify machine specifications before using tools.

Improper Cutting Parameters

Wrong feed rates and spindle speeds lead to a shortened tool life and workpiece defects. So, depending on the type of tool, the material, and the finish you want, you will tweak your cutting parameters.

Skipping Tool Maintenance

Lack of care for everyday tools leads to inefficiency and a higher impact on the budget. Familiarity with tools will allow you to handle them more effectively and maximize performance.

These mistakes should be avoided, as they lead to less downtime, better part quality, and longer tool life. Consider the follow-up process during planning; being proactive can be a time and energy saver.

CNC Lathe Machining Efficiency: How to Maximize?

CNC machining must be efficient to remain competitive. You must refine your tool selection and machining processes to ensure maximum productivity, minimal cost, and uncompromising quality. These practical tips will help you maximize your CNC lathe operations.

Utilize Good Quality Cutting Instruments

At first, buying high-quality cutting tools may appear expensive. But these multi-tools are more durable and better performing. Further, fewer tool changes and more uniform part quality translate into saving time and money.

Optimize Cutting Parameters

It’s usually challenging to operate your machine at the optimum speed and feed rate. Too slow means the chances are higher, and you will waste time. Go too fast, and you risk tool breakage and a poor finish. For cutting parameters, consult with tool manufacturers.

Apply Tool Coatings

Tools with coatings provide improved heat resistance and lower friction. Coatings, like TiN (titanium nitride) or Al₂O₃ (aluminum oxide), can also be applied, which can increase tool life in high-speed applications. Moreover, coated tools have less downtime and more efficiency.

Easy to Follow & Keep Up with Regular Tool Maintenance

Regular checking and care are crucial for tools. Keep tools clean and sharpened to ensure cutting efficiency. Replace worn tools on time to prevent part defects and machine damage.

Use Advanced Tool Monitoring Systems

Most CNC lathes today have a tool monitoring system. These systems continuously monitor tool wear and vibration. They also assist machinists in making the most of tool use and avoiding unplanned failures.

Choose the Right Coolant

Adequate cooling minimizes heat accumulation and extends tool life. Select the proper type and amount of refill fluid for your application. Coolant also improves surface finish and reduces the risk of thermal damage.

It is time to balance the power, precision, and strength to maximize efficiency. Manufacturers can save costs and enhance overall performance by adopting best practices and taking a proactive approach.

Final Thoughts:

Ultimately, choosing the appropriate lathe-cutting tools is essential for maximizing efficiency and precision. Using knowledge of tool materials, geometry, and machining techniques can help reduce costs and improve part quality. Perfection through avoidance of common mistakes, tool wear, and orchestration of your tools to be project-specific for each piece you work on.

Meeting Modern Machining Needs with Premium Parts Solutions

Are you looking for a reliable partner in CNC lathe machining, custom parts manufacturing, or toolmaking? Precision Parts offers high-precision solutions to meet your needs.

Upload your CAD file to get a comprehensive Design for Manufacturing (DFM) report from our experts for design optimization. With our experienced engineers and advanced CNC technology, you can be sure your parts consistently meet high-quality standards, Making Premium Parts the top choice for industrial enterprises.

We offer high-quality, low-cost, on-time delivery solutions for rapid prototypes as well as mass-produced items.

FAQ’s

Q1: What are some common lathe-cutting tools?

Tools for Furrow, Facing, Separating, Drilling, Threading, beveling, and Slotting serve a specific function depending on the process. Carbide tools are the best in terms of speed, as they are the hardest and can resist high heat.

Q2: How do you select the appropriate tool for CNC turning?

The tool should be compatible with the workpiece material, geometry, and machine. Balance cost and performance.

Q3: What do you mean by tool wear, and how do I reduce it?

Heat and friction are two of the main factors in tool wear. To minimize it, use coated tools, optimize speeds, and maintain your tools regularly.

Q4: When should lathe cutting tools be replaced?

Tools should be replaced when you notice that they are wearing, have poor finishes, or are not as accurate. Regular inspection is key.